Rotary drum screen

The equipment is a special rake teeth made of ABS engineering plastics, nylon or stainless steel, which are installed on the rake teeth shaft in a certain order to form a closed rake teeth chain.

Keywords:

Category:

Mechanical Screen

Product description

ZG Rotary drum screen cleaner, referred to as Rotary drum screen cleaner for short, is applicable to industrial wastewater and domestic wastewater treatment projects, intercepting floating debris and sediments in water, integrating four functions of sewage interception, slag removal, spiral lift and press dehydration. It is the most advanced and efficient screen cleaner in China at present, especially applicable to projects such as environmental sanitation or abattoir manure treatment.

Operating principle

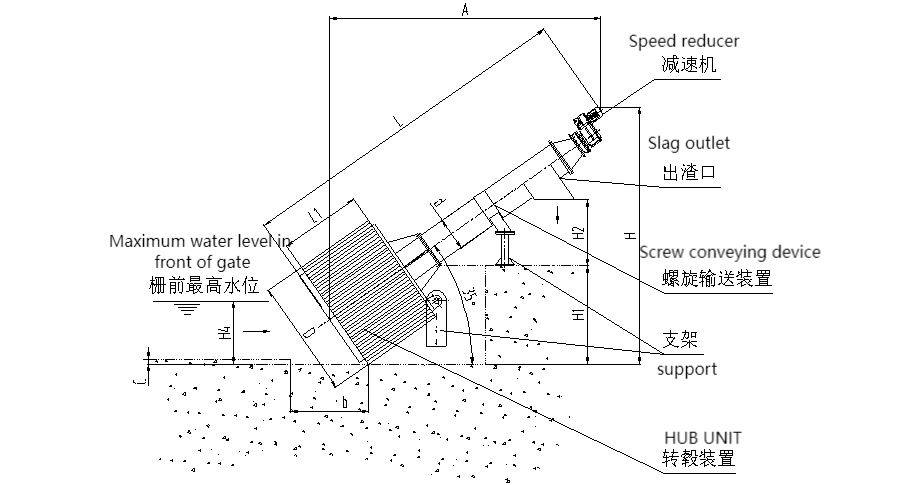

The equipment is installed in the channel at an angle of 35 ° with the horizontal plane. The sewage flows into the drum from the end of the rotating hub, and the water flows out from the grating gap. The grating intercepts the floating debris and sediments. With the increase of the intercepting flow, the filtration area gradually shrinks, and the head loss gradually increases. When the water level difference inside and outside the rotating hub reaches the set value, the rakes automatically rotate to remove the grating slag and discharge it into the slag collecting hopper in the drum. The grating slag is lifted by the built-in screw conveyor. The upward side of the grating slag is drained while the grating slag is discharged to the top end for squeezing and dewatering. The slag is discharged into the slag storage container for outward transportation.

Main technical parameters

1) GSZG-A (trash removal by rotation of outer hub)

model GSZG-A | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 3000 | ||

HUB DIAMETER D (mm) | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 3000 | ||

Diameter of conveying pipe d (mm) | 219 | 273 | 273 | 273 | 360 | 360 | 360 | 500 | 500 | 500 | 500 | 710 | ||

Grid length L1 (mm) | 650 | 830 | 985 | 1160 | 1370 | 1500 | 1650 | 2000 | 2200 | 2200 | 2400 | 3000 | ||

Maximum water level H4 | 400 | 500 | 670 | 800 | 930 | 1100 | 1200 | 1300 | 1500 | 1680 | 1800 | 2100 | ||

b (mm) | 125 | |||||||||||||

c (mm) | 40 | |||||||||||||

Mounting angle | 35° | |||||||||||||

Depth of channel H1 (mm) | H1=600~2500 | |||||||||||||

Slag discharge height H2 (mm) | H2=800~2000 | |||||||||||||

(mm) Equipment installation height H (mm) | H=H1+H2+H3 | |||||||||||||

Installation length A (mm) | A=Hx1.43-0.48D | |||||||||||||

Total length of equipment L(mm) | L=Hx1.74-0.75D | |||||||||||||

Liquid flow rate(m/min) | 1 | |||||||||||||

Water flow rate | Gate gap | 0.5 | 80 | 135 | 237 | 310 | 450 | 586 | 745 | 920 | 1130 | 1380 | 2080 | 2410 |

1 | 125 | 219 | 370 | 507 | 723 | 954 | 1209 | 1494 | 1803 | 2150 | 3280 | 4120 | ||

2 | 190 | 330 | 558 | 765 | 1095 | 1443 | 1832 | 2260 | 2732 | 3254 | 4530 | 5600 | ||

3 | 230 | 400 | 684 | 936 | 1340 | 1760 | 2235 | 2756 | 3334 | 3968 | 5450 | 6780 | ||

4 | 237 | 432 | 720 | 1010 | 1440 | 2050 | 2700 | 3340 | 4032 | 4680 | 6230 | 7560 | ||

5 | 252 | 468 | 795 | 1108 | 1576 | 2200 | 2934 | 3600 | 4356 | 5220 | 6750 | 8220 | ||

2) GSZG-B (trash removal by rake teeth rotation)

model GSZG-B | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | ||

HUB DIAMETER D(mm) | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | ||

Diameter of conveying pipe d (mm) | 219 | 273 | 273 | 300 | 300 | 360 | 360 | 500 | 500 | 500 | 500 | 700 | 700 | ||

Grid length L1 (mm) | 500 | 620 | 700 | 800 | 1000 | 1150 | 1250 | 1350 | 1450 | 1650 | 1950 | 2150 | 2400 | ||

Maximum water level H4 | 350 | 450 | 540 | 620 | 750 | 860 | 960 | 1050 | 1150 | 1280 | 1490 | 1630 | 1800 | ||

Width of gate channel B (mm) | 650 | 850 | 1050 | 1250 | 1450 | 1650 | 1850 | 2070 | 2270 | 2470 | 2670 | 2870 | 3070 | ||

Mounting angle | 35° | ||||||||||||||

Depth of channel H1 (mm) | H1=600~3000 | ||||||||||||||

Slag discharge height H2 (mm) | H2=800~2000 | ||||||||||||||

Equipment installation height H (mm) | H=H1+H2+H3 | ||||||||||||||

Installation length A (mm) | A=Hx1.43-0.48D | ||||||||||||||

Total length of equipment L(mm) | L=Hx1.743-0.75D | ||||||||||||||

Liquid flow rate(m/min) | 1 | ||||||||||||||

Water flow rate | Gate gap | 6 | 314 | 590 | 962 | 1263 | 1892 | 2475 | 3015 | 3775 | 4568 | 5757 | 7765 | 9372 | 11290 |

8 | 357 | 676 | 1080 | 1414 | 2145 | 2778 | 3505 | 4250 | 5130 | 6477 | 8773 | 10554 | 12740 | ||

10 | 385 | 731 | 1172 | 1534 | 2325 | 3021 | 3787 | 4594 | 5546 | 7000 | 9482 | 11439 | 13795 | ||

12 | 406 | 769 | 1238 | 1625 | 2487 | 3183 | 4000 | 4857 | 5900 | 7425 | 10042 | 12090 | 14586 | ||

Contact Us

Service Phone

Address

Room 1404a, Block a, Building 3, No. 20 Zhuzhou Road, Laoshan District, 266000, Qingdao, Shandong, China

What Makes Us So Different From Other Suppliers?

Committed to providing our customers with sufficient supply, stable and reliable quality, a variety of products and high-quality services.

Sourcing Company

Quick Quote

Help with selection

After-sales service

Support customization

Need Assistance? We're Here To Help!

To request a quotation or locate your local distributor, please fill out the form below.lf you cannot find the product you need.

feel free to contact us at +86-15954836111 or rope@njlanwu.com, and we will respond to you within i hour.

Factory Environment

At present, it has the design and manufacturing capacity of 15 series of water treatment special equipment and pump products

Product Applications

The company's products are spread all over the world and play an active role in promoting the world's environmental governance.

Customer visits

We warmly welcome your arrival and hope that our efforts can bring you an extraordinary experience.

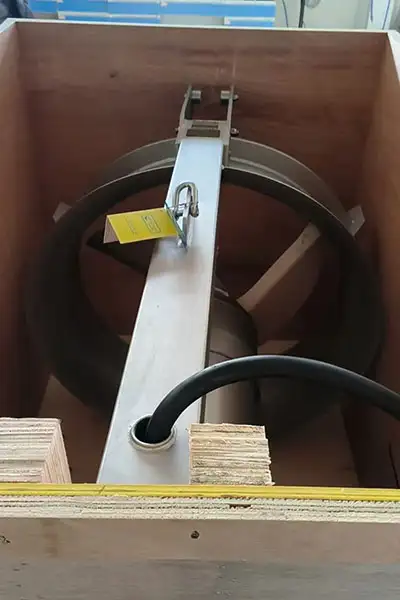

Transportation and Packaging

Efficient, flexible, and reliable, able to meet customers' needs for global logistics

FAQ

It is our responsibility to solve your problem

Where is your company?

Room 1404a, Block a, Building 3, No. 20 Zhuzhou Road, Laoshan District, 266000, Qingdao, Shandong, China

What certificates do you have?

We are ISO 9001and CE certified.

Are you a factory or a trading company?

We are an integrated production and sales company.

What is the MOQ of the product?

Different products have different MOQ's. Most products are usually one piece.

How about your delivery time?

Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

What are the payment options?

T/T payment is preferred,other payment methods are also accepted.

Other Products

With water treatment technology as the core, specializing in providing a series of services including water treatment technology, water treatment equipment, sewage treatment engineering design and equipment installation.

QJB Low Speed Submersible Mixer